Sand Casting Foundry China: A Comprehensive Guide to Choosing the Right Manufacturer

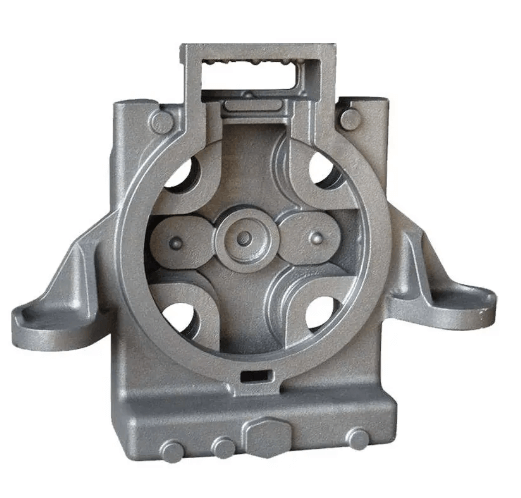

Sand casting is a widely used method for producing metal parts in the manufacturing industry. It involves pouring molten metal into a mold made of sand, which is then allowed to cool and solidify. Sand casting foundries in China have become increasingly popular due to their cost-effective and efficient production processes.

China has a long history of metalworking, and sand casting has been used in the country for centuries. Today, China is one of the largest producers of cast metal products in the world, with a significant portion of this production coming from sand casting foundries. These foundries use a variety of sand types and casting techniques to produce high-quality metal parts for a wide range of industries, including automotive, aerospace, and construction.

Sand casting foundries in China offer a number of advantages over other manufacturing methods. For one, sand casting is a relatively simple and inexpensive process, making it ideal for producing large quantities of metal parts. Additionally, sand casting allows for the creation of complex shapes and designs that might be difficult or impossible to achieve with other methods. With its long history of metalworking and its commitment to innovation, China’s sand casting foundries are poised to continue playing a major role in the global manufacturing industry for years to come.

Overview of Sand Casting Foundry China

China is one of the leading countries in the world when it comes to sand casting foundries. The country has a long history of metalworking, and its foundries are known for producing high-quality castings at competitive prices.

Sand casting is a popular manufacturing process in China, and it is used to produce a wide range of products, including automotive parts, aerospace components, and industrial machinery. The process involves pouring molten metal into a sand mold, which is then allowed to cool and solidify.

One of the advantages of sand casting is that it allows for the production of complex shapes and designs. This makes it a popular choice for manufacturers who need to produce parts with intricate geometries. Sand casting is also a relatively inexpensive process, which makes it an attractive option for companies looking to keep their production costs low.

China has a large number of sand casting foundries, ranging from small, family-owned businesses to large, multinational corporations. These foundries use a variety of materials, including iron, steel, aluminum, and brass, to produce castings of different sizes and shapes.

Overall, the sand casting foundries in China are known for their high quality, competitive pricing, and ability to produce complex parts. As a result, many companies around the world choose to work with Chinese foundries to meet their manufacturing needs.

Key Players in China’s Sand Casting Foundry Industry

China is one of the leading countries in the sand casting foundry industry. There are numerous companies that contribute to the industry’s growth and development. Here are some of the key players in China’s sand casting foundry industry:

1. Dongying Hengke Metal Co., Ltd.

Established in 2004, Dongying Hengke Metal Co., Ltd. is a professional manufacturer of investment casting and sand casting products. The company has a strong reputation for providing high-quality products and services to its clients. They specialize in producing precision casting and sand casting parts for industries such as automotive, construction, and machinery.

2. Ningbo Yinzhou Fuchun Precision Casting Co., Ltd.

Ningbo Yinzhou Fuchun Precision Casting Co., Ltd. is a leading manufacturer of sand casting products in China. The company has been in operation for over 30 years and has a strong reputation for producing high-quality products. They specialize in producing sand casting parts for the automotive, aerospace, and marine industries.

3. Qingdao Chifine Machinery Co., Ltd.

Qingdao Chifine Machinery Co., Ltd. is a professional manufacturer of sand casting products in China. The company has been in operation for over 20 years and has a strong reputation for producing high-quality products. They specialize in producing sand casting parts for industries such as automotive, agriculture, and construction.

4. Shandong Jingyanggang Metal Equipment Co., Ltd.

Shandong Jingyanggang Metal Equipment Co., Ltd. is a leading manufacturer of sand casting products in China. The company has been in operation for over 20 years and has a strong reputation for producing high-quality products. They specialize in producing sand casting parts for industries such as automotive, machinery, and construction.

These are just a few of the key players in China’s sand casting foundry industry. These companies have a strong reputation for producing high-quality products and services and have contributed greatly to the industry’s growth and development.

Technological Advancements in Chinese Sand Casting Foundry

Automation in Sand Casting

Chinese sand casting foundries have made significant strides in automating their production processes. The use of robotics and computer-controlled machinery has greatly improved the precision and speed of sand casting production. This has resulted in increased efficiency, reduced lead times, and improved product quality.

One of the most significant advancements in automation has been the use of 3D printing technology to create sand molds. This technology allows for the production of highly complex shapes and designs that would have been impossible to achieve using traditional sand casting methods. With 3D printing, sand molds can be produced in a matter of hours, reducing lead times and allowing for faster production.

Innovation in Material Use

In addition to automation, Chinese sand casting foundries have also made significant advancements in the materials used in production. Foundries are now using advanced materials such as carbon fiber, aluminum, and titanium to produce high-quality castings. These materials offer improved strength, durability, and resistance to corrosion, making them ideal for use in a wide range of applications.

Foundries are also using advanced coatings and surface treatments to improve the performance of castings. These treatments can improve the wear resistance, corrosion resistance, and thermal stability of castings, making them more durable and longer-lasting.

Overall, the technological advancements in Chinese sand casting foundries have greatly improved the efficiency, quality, and performance of sand casting production. With continued investment in automation and materials research, Chinese foundries are well-positioned to remain at the forefront of the sand casting industry for years to come.

Quality Standards and Regulations in China

Government Regulations

China has a well-established regulatory system for the foundry industry. The regulatory framework is overseen by the State Administration for Market Regulation (SAMR) and the National Development and Reform Commission (NDRC). The government has implemented strict quality control measures to ensure that the products manufactured meet the required standards.

The Chinese government has set up a comprehensive regulatory framework for foundries. The regulations cover various aspects of the manufacturing process, including the use of raw materials, production techniques, and environmental protection. In addition, the government has established a certification system for foundries to ensure that they comply with the regulations.

International Standards

China has adopted international standards for quality control and environmental protection. The International Organization for Standardization (ISO) has established a set of standards for the foundry industry, and Chinese foundries are required to comply with these standards.

The ISO 9001 standard is a quality management system that ensures that the products manufactured meet the required quality standards. The ISO 14001 standard is an environmental management system that ensures that the manufacturing process is environmentally friendly.

Chinese foundries have been certified by international organizations such as the American Bureau of Shipping (ABS) and the Det Norske Veritas (DNV) to ensure that they meet the required standards. These certifications are recognized globally and are a testament to the quality of the products manufactured by Chinese foundries.

In conclusion, China has a well-established regulatory system for the foundry industry. The government has implemented strict quality control measures, and Chinese foundries are required to comply with international standards. This ensures that the products manufactured by Chinese foundries meet the required quality standards and are environmentally friendly.

Economic Impact of Sand Casting Foundry China

Sand casting foundry is a vital component of the manufacturing industry in China, contributing significantly to the country’s economic growth. The process involves pouring molten metal into molds made of sand to produce various metal parts and components used in the automotive, aerospace, and construction industries.

The sand casting foundry industry has created numerous job opportunities for the Chinese population, providing employment for over 1 million people. The industry has also attracted foreign investors, boosting the country’s foreign direct investment and improving its balance of payments.

In addition, sand casting foundry has contributed to the development of other industries in China, such as the mining and transportation industries. The demand for raw materials like sand, clay, and coal has increased, leading to the expansion of these industries and the creation of more jobs.

Furthermore, the sand casting foundry industry has helped to promote technological innovation in China. The industry has invested heavily in research and development, resulting in the development of new and improved casting techniques. This has improved the quality of metal parts produced, making them more durable and efficient.

Overall, the sand casting foundry industry has had a significant impact on the Chinese economy, contributing to the country’s GDP and promoting economic growth. With the continued growth of the manufacturing industry in China, the sand casting foundry industry is expected to continue to play a vital role in the country’s economic development.

Challenges Facing China’s Sand Casting Foundry

China’s sand casting foundry industry has experienced significant growth in recent years, but it has also faced several challenges. Some of the main challenges facing China’s sand casting foundry industry are as follows:

1. Environmental Regulations

China has been tightening its environmental regulations in recent years, which has had a significant impact on the sand casting foundry industry. The foundries have had to invest in new equipment and technologies to comply with the new regulations, which has increased their operating costs. This has been a major challenge for many foundries, particularly smaller ones that may not have the financial resources to make the necessary investments.

2. Competition from Other Countries

China’s sand casting foundry industry faces competition from other countries, particularly India and Vietnam. These countries have lower labor costs and are able to produce castings at a lower cost than Chinese foundries. This has put pressure on Chinese foundries to reduce their costs and improve their efficiency to remain competitive.

3. Skilled Labor Shortage

The sand casting foundry industry requires skilled workers to operate the equipment and produce high-quality castings. However, there is a shortage of skilled workers in China’s foundry industry. Many young people are not interested in working in the foundry industry due to the difficult working conditions and low pay. This has made it difficult for foundries to find and retain skilled workers.

4. Quality Control

Quality control is a critical issue in the sand casting foundry industry. Chinese foundries have faced criticism in the past for producing low-quality castings. This has damaged the reputation of the industry and made it difficult for Chinese foundries to compete with high-quality foundries in other countries. To address this challenge, many Chinese foundries have invested in new quality control systems and processes to improve the quality of their castings.

In conclusion, China’s sand casting foundry industry faces several challenges, including environmental regulations, competition from other countries, skilled labor shortages, and quality control issues. These challenges will require the industry to continue to innovate and improve to remain competitive in the global market.

Future Prospects of Sand Casting Foundry China

China has been one of the leading countries in the manufacturing industry, including the production of sand casting foundry. In recent years, the industry has experienced a significant growth rate, and the future prospects look promising.

One of the main factors that contribute to the growth of the sand casting foundry industry in China is the increasing demand for industrial machinery and equipment. The country’s industrial sector is expanding, and the demand for high-quality and cost-effective machinery components is rising. Sand casting foundry provides a cost-effective solution for producing large and complex machinery parts, which makes it a popular choice for many manufacturers.

Moreover, the Chinese government has been actively promoting the development of the manufacturing industry, including the sand casting foundry sector. The government has implemented policies and regulations that support the industry’s growth and innovation, such as tax incentives and subsidies. These initiatives have encouraged many companies to invest in sand casting foundry, which has resulted in the industry’s expansion.

In addition, the advancement of technology has also contributed to the sand casting foundry industry’s growth in China. The development of 3D printing technology has enabled manufacturers to produce more complex and intricate parts, which were previously impossible to manufacture using traditional casting methods. This has opened up new opportunities for the sand casting foundry industry, and many companies have started to adopt this technology to improve their production process.

Overall, the future prospects of the sand casting foundry industry in China look bright. With the increasing demand for industrial machinery and equipment, government support, and technological advancement, the industry is expected to continue to grow and innovate in the coming years.